INSTRUCTIONS

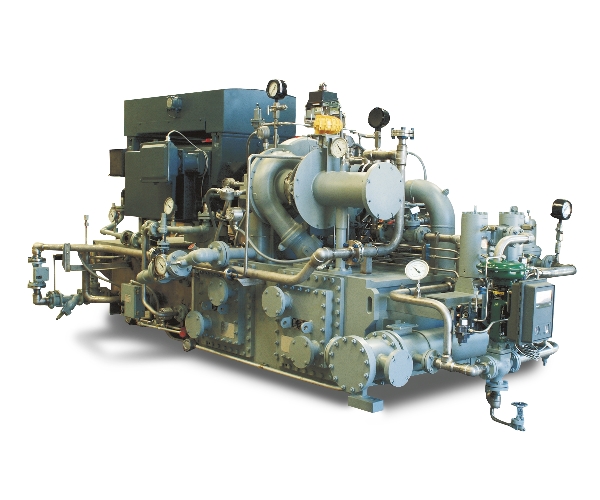

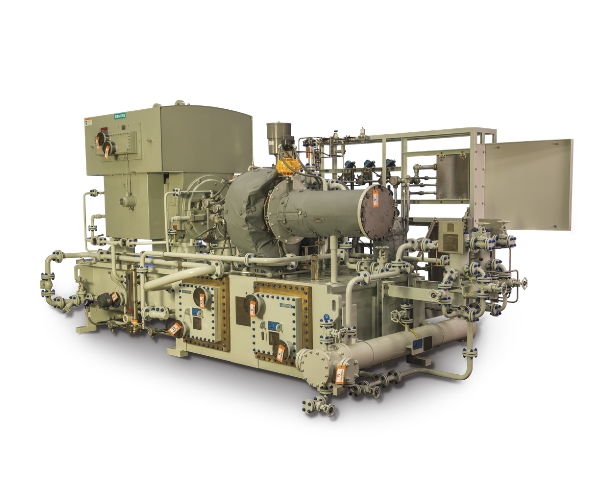

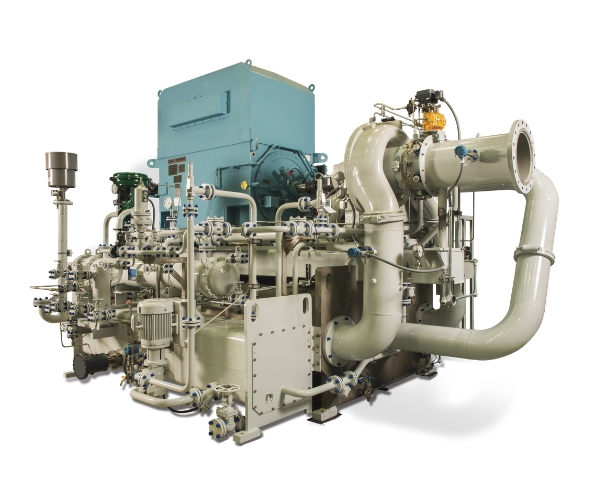

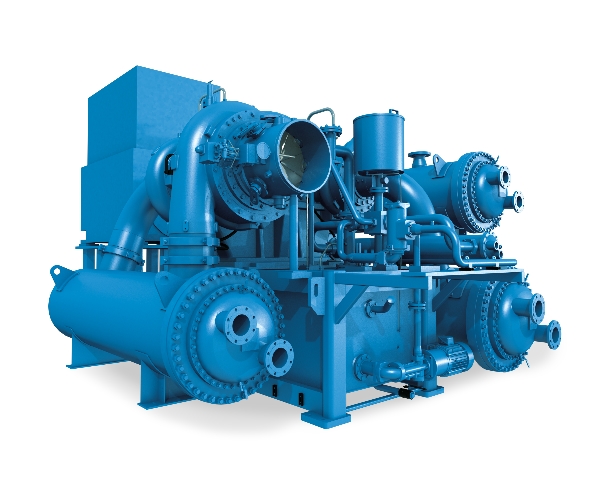

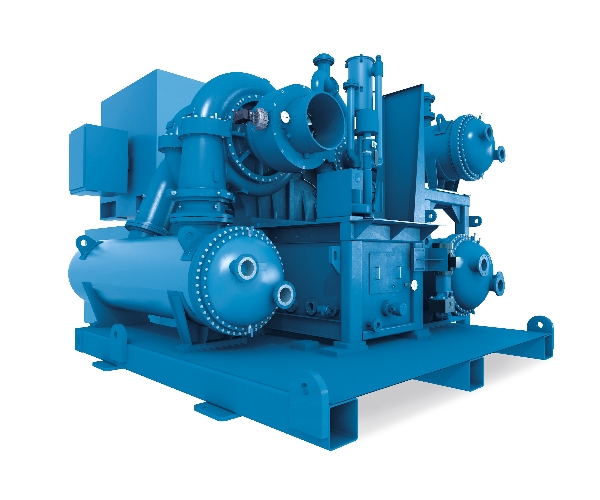

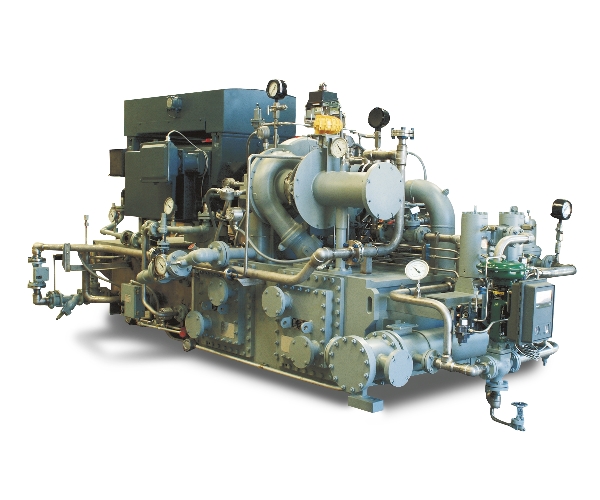

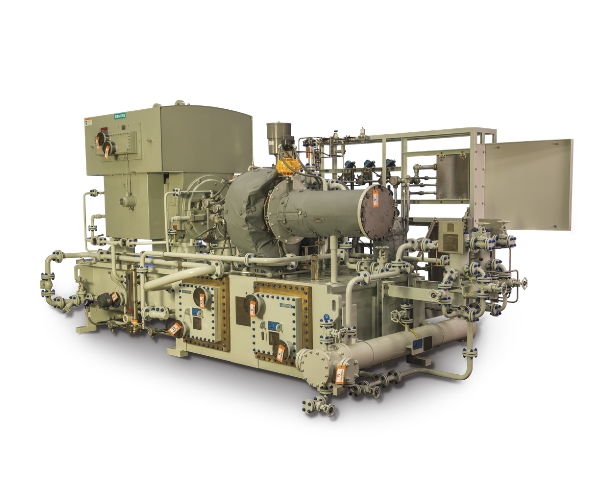

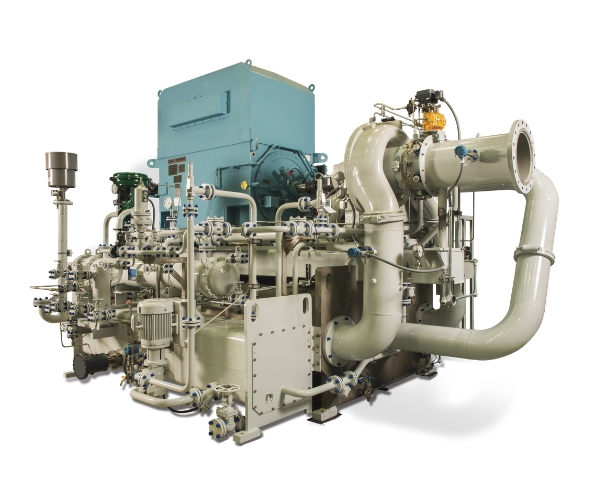

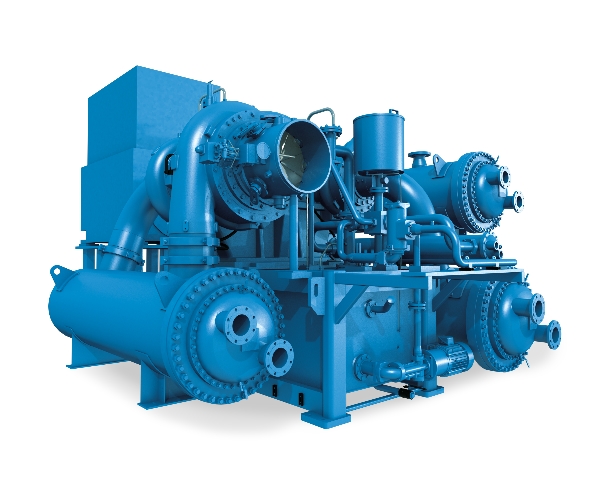

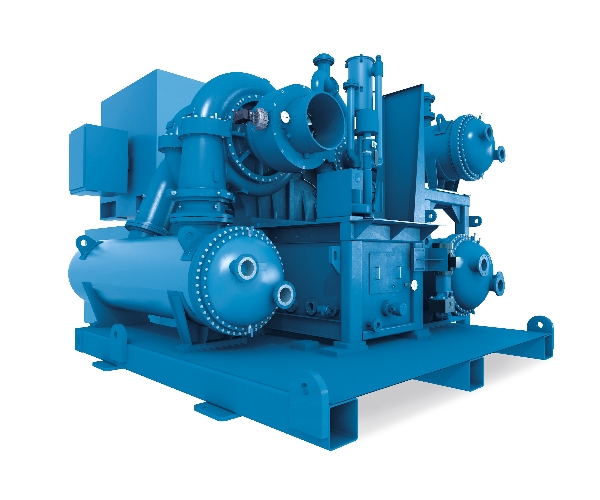

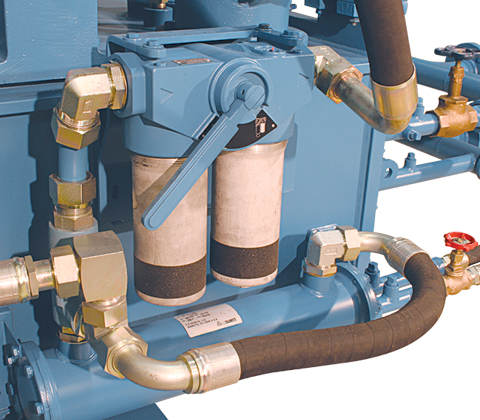

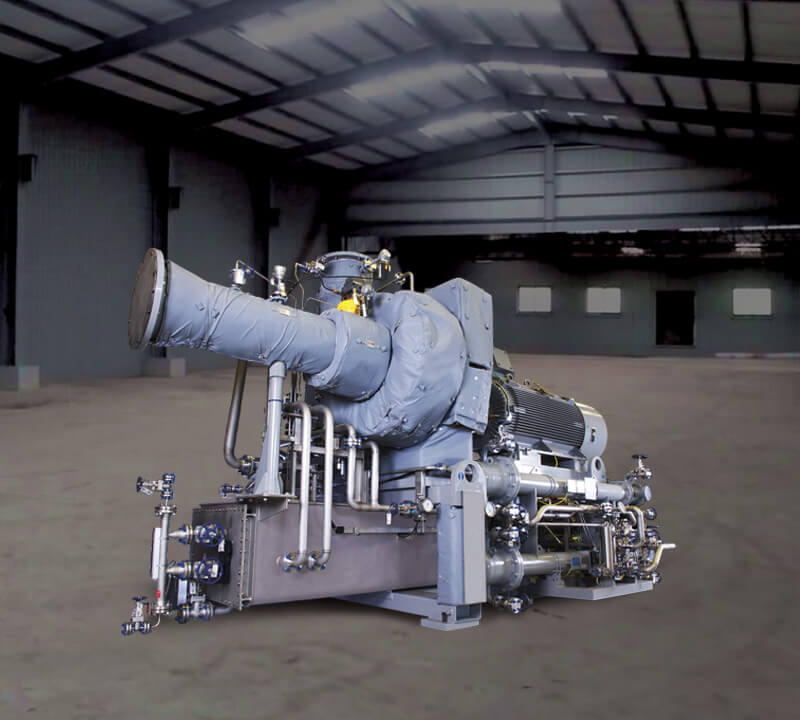

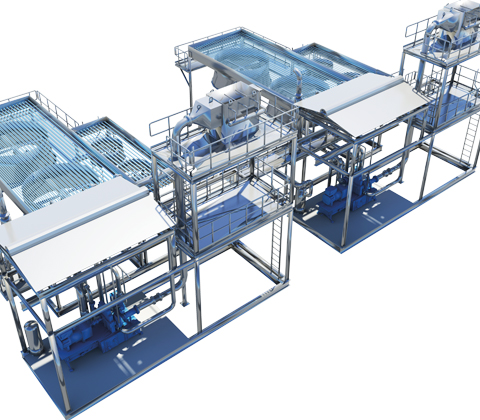

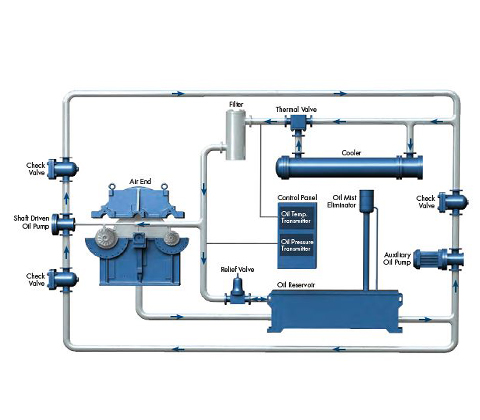

For more than 50 years, FS-Elliott has been a supplier of centrifugal air compressors for industrial and engineering use. The FS-Elliott compressor series consists of a complete range of models, built-in with sophisticated tilted impellers made of 17-4PH stainless steel. These compressors are reliable, using high-tech coaxial rotary gears, one-piece high-rigidity casings, bundle coolers in water piping, horizontally split seals, self-correcting high-load capacity bearings, low-friction tilting pad bearings, and 4-in-1 modular advanced controllers.

The PAP Plus series is rugged, reliable, and meets the API672 specification. The unit can be customized to meet the needs of users in strict accordance with the customer's technology and operating parameters, especially in the fields of oil, gas, oil refining, chemical/petrochemical, etc. Each PAP Plus must pass through strict quality control and technical standards, carry out production processes in accordance with ISO9001:2008 specifications, and perform unit testing following API672 and ASME power specifications. As the number of stages increases, the compression ratio lowers the efficiency increases. Up to four levels are available, making it 5% more efficient than older compressor designs.

The compressors are designed with 2-stage, 3-stage, and 4-stage operating pressures ranging from 3 to 31 kg/cm2 (40 to 450 psig). They run between 185kW and 4475kW (250HP~6000HP), and yield discharge volumes from 900 to 24500 CFM (25~695 m3/min).

Features

applications

Online

Chat

Online

Chat