INSTRUCTIONS

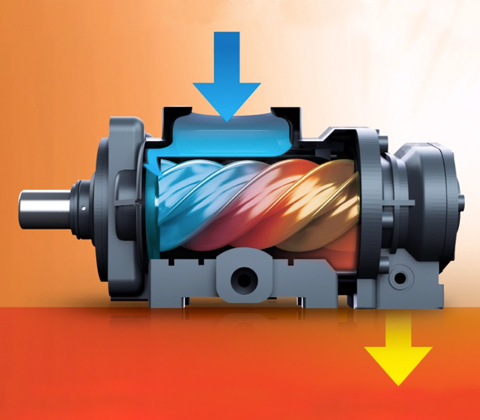

The SL series low-pressure screw compressor uses airends specially designed for low-pressure applications. The rotor clearance and the housing of the airend are precisely designed with the exhaust source altered, the bearing pedestal enlarged, and all the airends adjusted to meet the requirements for large air delivery and low pressure. The unit outputs the pressure that is needed directly and avoids energy loss from over-compression, re-expansion, and leakage, thus saving over 25% of energy usage. The entire system runs under low-pressure, which lowers the amount of stress and heat load that is placed on the parts. This enables compressor operation that is more stable with a longer service life.

Features

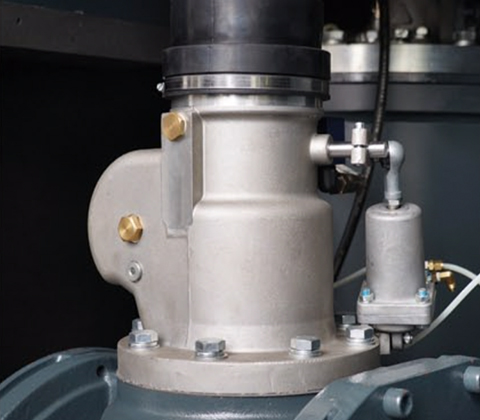

The combined functions of anti-reverse, oil-breaking, and capacity control

are integrated, and the low-pressure drop design optimizes the suction

efficiency. When running, it can automatically adjust according to the

change of the actual compressed air demand and have a more precise control

of the unloading pressure.

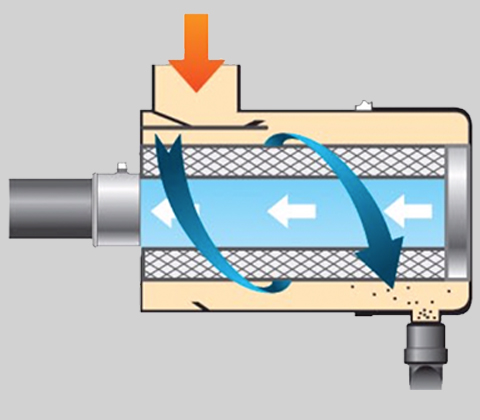

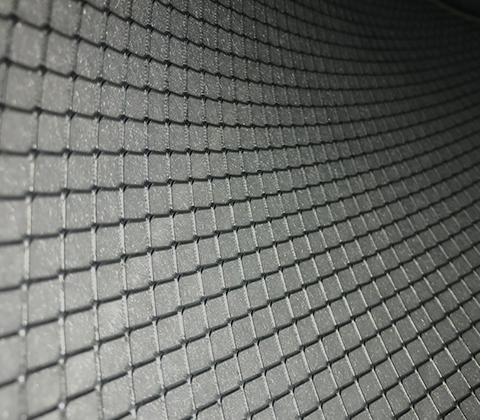

The enlarged oil separator design provides a larger oil separation area. In

addition to the improved filtering effect, it also reduces the pressure

drop generated during the oil separation process. The oil gas tank cover

adopts Fusheng’s patented spindle design, which makes the replacement of

oil separator elements simpler.

applications

Online

Chat

Online

Chat