INSTRUCTIONS

-

Features

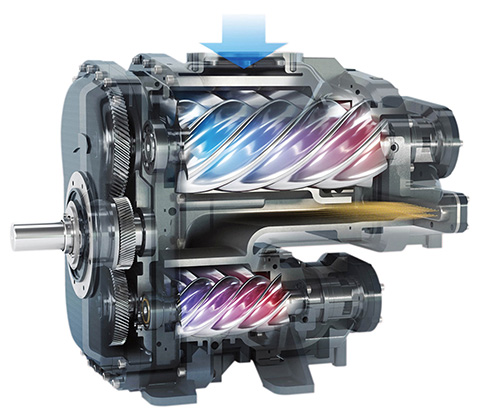

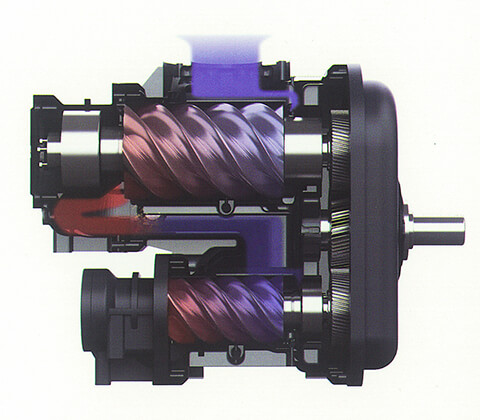

Cold oil is injected into the machine between the first and second stages

of the airend for cooling, which has been shown to tremendously decrease

compressed air loss. The injection of oil also helps to maintain the

compressed air’s pressure dew point at an optimal level, preventing water

formation, corrosion, and system oil emulsification.

e-COOL™ is environmentally-friendly technology that combines a smart

compressor layout, strategic component selection and location, and cooling

airflow and operation to minimize the impact of temperature on a

compressor’s efficiency and reliability. A combination of high efficiency

front-tilted centrifugal fans and independent cooling channels are adopted

in the design to guarantee strong forced convection and cooling effects.

The decreased thermal stress extends the life of components and lowers

internal compressor temperatures, resulting in better volumetric and

electrical efficiency.

.jpg)

-m.jpg)

Online

Chat

Online

Chat